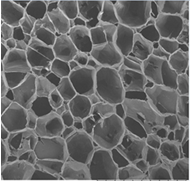

Anhui Star-Better's self-produced microporous polymer carrier

1Product Introduction

Anhui Star-Better's self-produced microporous polymer carrier is a new type of polymer material with high porosity and a three-dimensional network like through-hole structure, which has excellent adsorption, filtration, and loading performance. By utilizing its capillary self adsorption effect, the microporous polymer carrier and liquid additives can be easily blended and adsorbed to obtain capsule like masterbatches with a dry surface and free flow.

IIperformance index

|

Brand |

Matrix resin |

Particle size (mm) |

Maximum adsorption rate* (%) |

Pile density (g/cm)3) |

|

MPC1002 |

PP |

1-4 |

25 |

0.27-0.33 |

|

MPC1005 |

PP |

1-4 |

50 |

0.15-0.20 |

|

MPC1010 |

PP |

2-4 |

70 |

0.09-0.15 |

|

MPC1020 |

PP |

3-5 |

80 |

0.05-0.09 |

|

MPC2005 |

PS |

2-4 |

55 |

0.15-0.25 |

|

MPC3110 |

LDPE |

2-5 |

20 |

0.20-0.30 |

|

MPC3111 |

LDPE |

2-3 |

40 |

0.15-0.30 |

|

MPC8010 |

ABS |

2-5 |

40 |

0.25-0.35 |

*Adsorption rate test: Adsorption is carried out according to the mass ratio, and the adsorption liquid is kerosene.

3、 Preparation method of masterbatch

By utilizing the unique capillary self adsorption effect, liquid or liquid convertible additives can be transformed into capsule like solid masterbatches with a dry and freely flowing surface through simple blending adsorption. The masterbatch transformation of liquid additives is no longer a processing difficulty. By using a low-speed mixing process, appropriate heating and negative pressure, the adsorption time can be shortened.

4、 Application characteristics of mother batch preparation

- The mother batch production process is simple: there is no need for extrusion granulation, no need for dispersants and co dispersants.

- Adjustable effective content of masterbatch: By controlling porosity and adsorption rate, the effective content can be adjusted below 80%.

- Especially suitable for thermosensitive additives: the preparation process has no thermal history, reducing the performance loss of thermosensitive additives.

- Outstanding performance of masterbatch: no precipitation, no stickiness, convenient for transportation, storage, addition, quantification, and dispersion.

- Convenient finished product testing: The effective content is extracted without the need for high-temperature melting of the resin.

- Low odor and low VOC: Compared to traditional mother batch production processes, it has no thermal shear and low content of small molecule volatiles.

5、 Application fields of microporous polymer carriers

|

Auxiliary agent form (room temperature 25 ℃) |

Category of additives |

|

liquid (viscosity<30000 cSt) perhaps Can be converted into liquid (Heating, solvent dissolution) |

Antistatic agents, light stabilizers, coupling agents, aromatics, initiators, maleic anhydride, peroxides, lubricants, anti fogging agents, foaming agents, flame retardants, toughening agents, bitterness agents, deodorizers, silicone, dry silane, anti drip agents, etc. |

6、 Packaging, storage and transportation of microporous polymer carriers

50-100 kg/ton bags or 10 kg/bag, the specific packaging category varies depending on the product model.

Transport as ordinary industrial products, store at room temperature, and avoid direct sunlight.