Low odor maleic anhydride grafted polypropylene compatibilizer ST-13LO

1、 Product Introduction

Polypropylene materials, due to their non polarity and crystallinity, have poor compatibility with other materials such as polar polymers and inorganic fillers, making it difficult to prepare useful blend materials. Therefore, it is necessary to add a compatibilizer to form a blend of originally incompatible polymers with unique properties that none of the components possess. Compatibilizers can reduce the interfacial tension between different materials and improve the interfacial adhesion between dispersed and continuous phases of blended species. So far, due to its low cost, high activity, and good processability, maleic anhydride grafted polypropylene (MAH-g-PP) is the most important functionalized polypropylene. It is present in polymer blends PP/inorganic fillers PP/organic fibers, composite reinforcement materials, and other aspects have a wide range of applications.

There are many methods for grafting maleic anhydride onto polypropylene, mainly including solution method, melting method, radiation method, and solid-phase method. Among them, the melting method is the most widely used, also known as reactive extrusion method. At present, the industrialized grafting of maleic anhydride onto polypropylene mainly uses diisopropylbenzene peroxide as the initiator, and the presence of unreacted free maleic anhydride leads to a high concentration of irritating small molecule volatiles in the material. This not only accompanies a pungent odor in the production process, which is not conducive to the health of workers, but also leads to excessive odor in downstream products, limiting its applicability.

Anhui Xingbeida has added a unique process design to the twin-screw extruder based on the traditional reaction extrusion processSecondary vacuum pumping deviceIt can better remove residual small molecule volatiles in reactants and solve the problem of irritating odors in the production process. In addition, by using VOC high-temperature removal equipment,Add VOC removal processBy fully volatilizing small molecules such as VOC in the product, low odor maleic anhydride grafted polypropylene compatibilizer product ST-13LO can be prepared.

2、 Product performance indicators

|

project |

unit |

ST-13LO |

|

Melt index (190 ℃, 2.16kg) |

g/10min |

60-100 |

|

MAH content |

% |

0.8-1.1 |

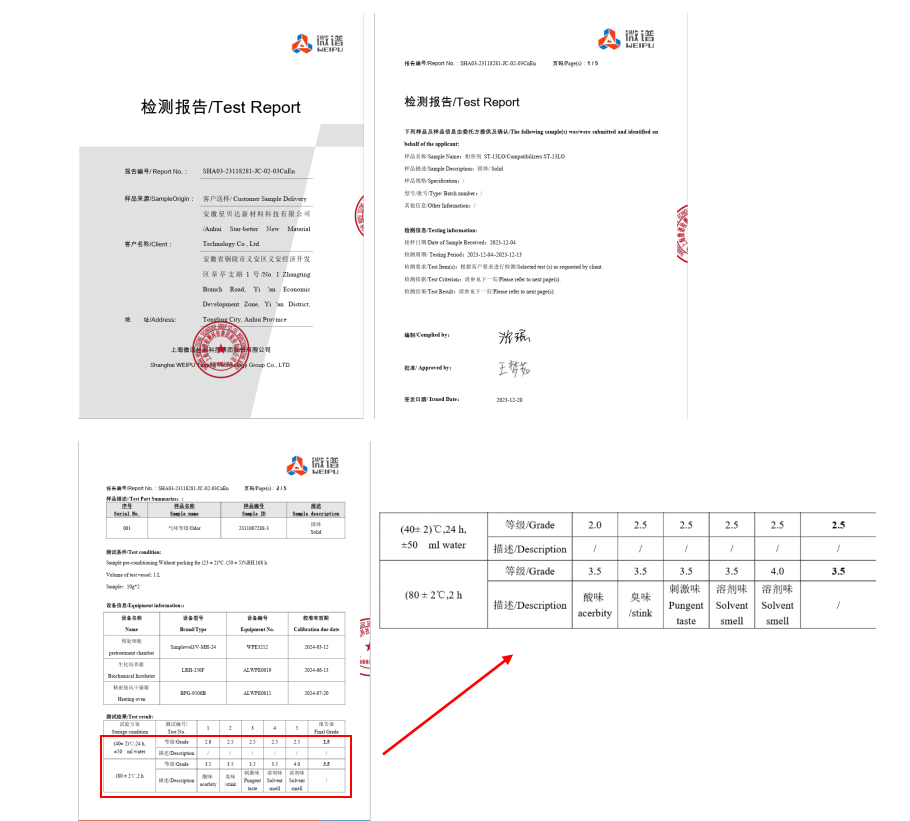

3、 Third party odor detection report

3、 Application field

A blending modification system for polypropylene, which has good interfacial compatibility with polar materials, improves the mechanical properties of the material, reduces the exposure of fiberglass, and is widely used in low odor demand fields such as household appliances and automotive interiors.

4、 Reference dosage

- The recommended addition amount for filling or reinforcing polypropylene is 3-8%.

- In PA/PP alloy, the recommended addition amount is 5-8%.